- Phone: +1 855 315 1115

- info@grandeinc.com

ACU-GATE (Porte de rinçage) - Grande Gestion des Eaux

- Home

- Rinçage des réservoirs et des égouts

- Products

- ACU-GATE (Porte de rinçage)

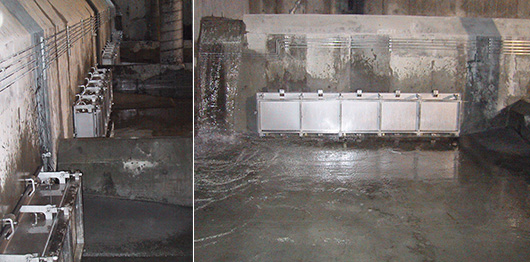

Le système de vanne de rinçage ACU-GATE est un dispositif d’évacuation des sédiments conçu pour éliminer les débris déposés dans les réservoirs de rétention des eaux pluviales, les réservoirs de rétention de trop-plein d’égouts unitaires (CSO), les réservoirs d’égalisation de trop-plein d’égouts sanitaires (SSO) et les fonds de réservoirs, ainsi que les égouts inversés, en utilisant une seule chasse d’eau. Il a été utilisé dans les applications CSO, SSO et peut être utilisé dans des applications agricoles et industrielles pour nettoyer n’importe quel réservoir, réservoir ou bassin de traitement par lots.

Le système fonctionne en libérant un torrent d’eau dans le système stocké derrière la vanne de chasse. La vague de chasse qui en résulte progresse sur toute la longueur du chemin de chasse, poussant les débris déposés devant elle. Les débris remis en suspension sont ensuite transportés par les eaux de chasse vers la station d’épuration pour être éliminés.

Le système de vanne de rinçage présente plusieurs avantages par rapport aux autres types de dispositifs de rinçage des sédiments. La vanne de chasse d’eau ACU-GATE est installée sur une ouverture en béton, au niveau du sol, située sur un mur à l’extrémité amont du chemin de chasse. Les composants mécaniques du système sont constitués du vérin hydraulique, de la charnière et du mécanisme de verrouillage. La porte de chasse d’eau ACU-GATE est entièrement construite en acier inoxydable robuste et comporte peu de pièces mobiles, assurant ainsi une longue durée de vie et pratiquement sans entretien. Le système de chasse des sédiments peut être installé dans de nouveaux réservoirs ou facilement installé dans des installations existantes. Les composants suivants sont inclus dans le système de vanne de rinçage ACU-GATE : la vanne de rinçage, le système d’ancrage, les tubes hydrauliques, les connecteurs de tubes, le système de support de tubes, le fluide hydraulique, l’unité de puissance hydraulique et le panneau de commande local.

Caractéristiques

-The most extended drainage wave

-Vérin simple ou double effet

-Low operating pressure

-Pneumatic operating mode (optional)

-Floating operating mode (optional)

-No fresh water supply required

-Nécessite peu ou pas d’entretien

-Facile à adapter aux installations existantes

-Stainless steel construction

Scope of application

La porte de chasse d’eau ACU-GATE peut varier du modèle GAG-20 au GAG-240. Le GAG-20 est conçu pour s’adapter à une ouverture en béton mesurant 16 pouces de haut sur 20 pouces de large (41 cm x 51 cm) et le GAG-240 est conçu pour s’adapter à une ouverture en béton mesurant 16 pouces de haut sur 240 pouces de large (41 cm). x 508 cm). La sélection du modèle ACU-GATE est basée uniquement sur la largeur du passage affleurant. Le volume de chasse d’eau requis stocké derrière la vanne de chasse est basé sur la longueur du chemin de chasse et la pente du fond du réservoir ou du radier d’égout. À ce jour, la longueur maximale de chasse d’eau est de 850 pieds (280 m).

Méthode de fonctionnement

La zone de stockage de l’eau de chasse est remplie chaque fois que le réservoir est utilisé. Il peut utiliser de l’eau in situ ou être rempli d’une source d’eau secondaire. Une fois le réservoir ou l’égout vidangé, la vanne de chasse d’eau ACU-GATE est prête à fonctionner. Le dispositif de chasse des sédiments est normalement en position fermée ou verrouillée. À l’aide de signaux électroniques activés par le niveau d’eau, le groupe hydraulique met sous pression le cylindre du portail, faisant ainsi tourner les loquets en position ouverte. La pression hydrostatique de l’eau de chasse stockée derrière la vanne provoque l’ouverture de la vanne de chasse ACU-GATE, entraînant la libération d’un torrent d’eau qui coule le long du canal de chasse, récurant tous les débris déposés du fond du réservoir ou du déversoir d’égout. . Une fois que le réservoir d’eau de chasse situé derrière le dispositif de rinçage des sédiments est vidé, le clapet de la porte revient à sa position verticale normale. À ce stade, le groupe hydraulique est arrêté et le ressort du vérin simple effet ramène le loquet en position fermée, assurant ainsi la fermeture du portail. La vanne de rinçage ACU-GATE est maintenant prête pour le prochain rinçage.

La vanne de chasse d’eau ACU-GATE peut également être actionnée en utilisant les niveaux d’eau du système à l’aide d’un actionneur hydraulique alimenté par flotteur, ne nécessitant ainsi aucune énergie externe. La porte de chasse d’eau ACU-GATE peut également être actionnée à l’aide d’un système d’alimentation pneumatique, éliminant ainsi le besoin de fluide hydraulique.

Situés sous le cadre du portail, les loquets de chasse d’eau ACU-GATE sont complètement protégés de l’accumulation de débris par le cadre du portail. Lors du déverrouillage, le mécanisme tourne vers le haut afin qu’un dégagement supplémentaire ne soit pas nécessaire sous le portail. Le cylindre de chasse d’eau du portail ACU-GATE est entièrement logé dans les limites du cadre du portail, aucun dégagement latéral supplémentaire n’est donc nécessaire.