- Phone: +1 855 315 1115

- info@grandeinc.com

ACU-JET jet regulator

- Home

- Flow Regulation

- Products

- ACU-JET jet regulator

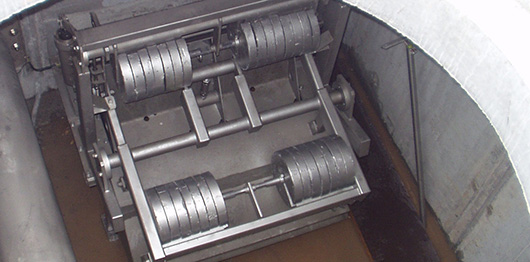

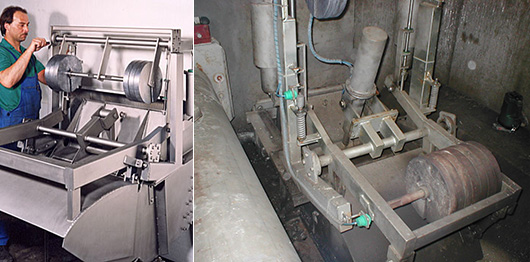

The ACU-JET jet regulation system is designed to maintain a constant and precise flow rate (+/- 5%) from a minimum of 235 gpm (15 L/s) to a maximum of 32,000 gpm (2,000 L/s) for upstream water levels varying from 0 to 40 feet (12 m). The ACU-JET jet regulator has been used for flow control in combined sewer systems (CSO), sanitary sewer systems (SSO), and batch treatment plant effluents, and is well-suited for regulating medium to very large discharges. The ACU-JET jet regulator is installed downstream of the control point in a dry well and does not require any differential head for proper operation.

Features

-235 gpm to 32,000 gpm (15 to 2,000 L/S)

-Waterhead up to 40 ft (12 m)

-No floor offset required

-Can be equipped for a remote operation

-Automatic rinsing effect which prevents blockage

-Design flow rate can be adjusted on site

-Easy to adapt to existing installations

-Stainless steel construction

Application scope

The ACU-JET jet regulator system can range from the GAJ-R-20 model to the GAJ-R-100/60 model. The GAJ-R-20 has an inlet diameter of 8 inches (20 cm) with a flow range of 235 to 1,030 gpm (15 to 65 L/s), while the GAJ-R-100/60 has an inlet opening of 40 inches (100 cm) wide by 24 inches (60 cm) high with a flow range of 20,800 to 32,000 gpm (1,300 to 2,000 L/s). The selection of the ACU-JET model is entirely based on the required flow range.

How it works

The ACU-JET jet regulator maintains a constant flow rate at a defined value, independent of the upstream water level. The ACU-JET jet regulator effectively balances the force of the water passing through it against the jet shield. The most important functional elements are the pivoting radial gate, the anti-jet shield, and the regulating counterweight. During low flow periods, the pivoting radial gate remains fully open. As the influent flow increases, it passes through the regulator housing and is directed against the jet shield. The increasing water force pushes the shield against the regulating counterweight's force. These two movements are transferred to the pivoting radial gate via coupled levers, triggering the regulation process. As the water force on the jet shield increases, the pivoting radial gate closes, reducing the discharge opening. The ACU-JET jet regulator's opening is automatically adjusted to match the upstream water level, resulting in a constant regulated flow.

The ACU-JET jet regulator is self-flushing to prevent blockages. If a blockage occurs, the flow rate through the regulator decreases, resulting in a corresponding reduction in the regulating force of the water on the jet shield. This causes the spray shield to drop and the radial door to open fully. This eliminates the blockage caused by the pressure of the upstream water level, after which the regulating process resumes.

Each ACU-JET Jet Regulator is calibrated on a fully functional, full-scale test rig. Each ACU-JET jet regulator is shipped to site pre-set to the desired design flow rate. In addition, setpoints are clearly marked for future in-situ flow adjustments (should this prove necessary). The controller can then be installed and commissioned without the need for time-consuming and costly in situ calibration or flow measurement.

The ACU-JET jet regulator can be fitted with a servo-control unit to change the design flow from fully open to closed. An ACU-JET jet regulator can be controlled locally or remotely from a central control location. In the event of a power failure, the regulator will continue to operate, automatically maintaining the constant discharge to which it was last set.