- Phone: +1 855 315 1115

- info@grandeinc.com

ACU-BEND Bending Weir

- Home

- Overflow Screening

- Products

- ACU-BEND Bending Weir

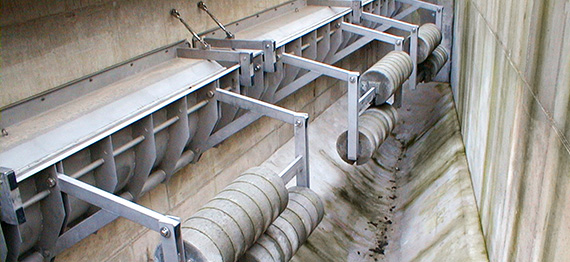

The ACU-BEND flexible weir system is designed to maintain maximum water levels upstream of the weir, allowing full utilization of all available upstream storage volume, without affecting overflow weir capacity in combined sewer overflow (CSO) applications. ACU-BEND's unique, patented and extensively tested design works by only allowing any excess water in the system to reach the receiving watercourse, but only once the design upstream water level has been reached. This increases the storage volume of tanks and sewers and reduces the frequency and volume of overflows, resulting in less water pollution. This enables the ACU-BEND to overcome the disadvantages inherent in fixed weirs. The ACU-BEND can also create a hermetic seal that protects against backflow and controls odours, as it is normally in the closed position.

The system's only mechanical components are lubrication-free plain bearings, reducing the need for maintenance and ensuring trouble-free, economical operation. The compact design of the ACU-BEND allows easy installation in new overflow structures, or can be easily retrofitted directly onto existing fixed weirs. The following components are included in the ACU-BEND bending weir system: bending weir flap, plain bearings, anchoring system, counterweights and inclinometer.

Features

-Integrated counterweight design

-Simple installation

-Maximizes on-site storage

-Constant, easily adjustable performance level

-Reduces overflow frequency

-Improved hydraulic quality line

-Backflow prevention and odor control

-Lower storage tank construction costs thanks to smaller volumes

-Easy to adapt to existing installations

Scope of application

The ACU-BEND bending weir vary from model GAB-30 to GAB-90. The GAB-30 is designed to hold 12 inches (30 cm) of water above the weir crest, and the GAB-90 holds 36 inches (90 cm) of water above the weir crest. ACU-BEND model selection is based entirely on the height of water storage required. Units are modular in design, with a single unit measuring up to 20 feet (6 m) in length. The hydraulic capacity of the ACU-BEND is at least equal to that of a standard weir.

System of operation

The ACU-BEND curved weir is installed on the downstream side and directly along the entire length of the overflow weir opening. The ACU-BEND flexible weir adapts to the overflow by pivoting upwards and opening from below.

The flexible weir mechanism is entirely passive, requiring no external energy to operate. Fixed counterweights act directly against the curved weir flap to maintain a constant upstream water level for all overflows varying from 0 to design flow. The ACU-BEND flexible weir will also accept flows above the design flow, resulting in a higher water level. The operating level can easily be adjusted on site by adding or removing counterweights.

The flexible weir consists of a structural frame attached to the overflow weir wall, a flap and an integrated counterweight structure. The ACU-BEND bending weir requires no control, although its operation can be monitored by an inclinometer. Upstream and downstream water levels can also be monitored.

The ACU-BEND flexible weir adapts to the overflow by opening at the bottom. As a result, some floating materials are retained upstream of the bend weir. At the end of the event, they are discharged at the bottom of the sewer, where they are carried by the dry weather flow to the wastewater treatment plant for collection and disposal.